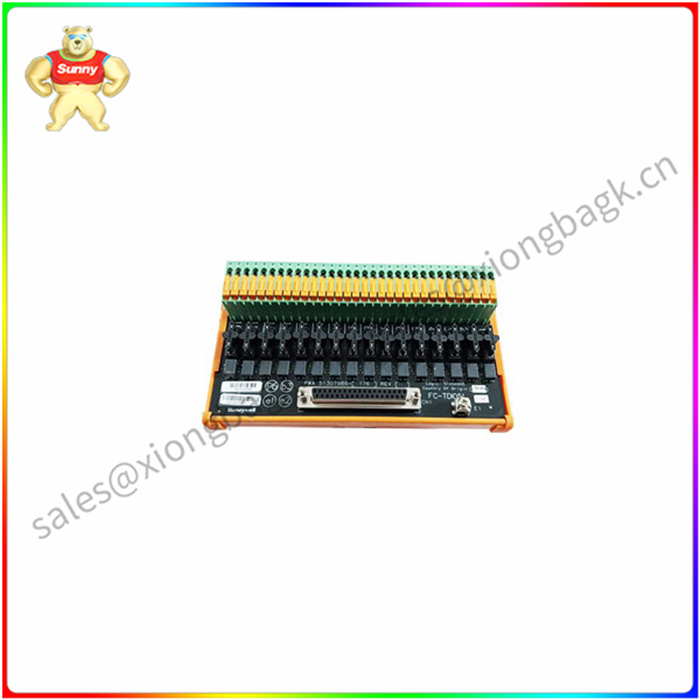

FC-TDIO51 HONEYWELL 为机器数据收集引入LMI人机界面

LETS机器接口从任何机器上收集生产数据马萨诸塞州阿克顿,2007年3月26日讯——霍尼韦尔(纽约证券交易所代码:HON) Wintriss今天推出了LETS机器接口(LMI ),这是一款操作员终端,能够从生产机器上收集信息,并输入霍尼韦尔的生产线效率跟踪软件(LETS)。

霍尼韦尔Wintriss产品线总监Mark Hatch表示:“LMI使我们能够为生产设备缺乏数据收集能力的客户提供强大的LETS系统功能。通过安装一个或多个LMI并连接到LETS,这些客户可以将生产数据输入ERP或制造执行系统(MES)软件,安排生产和总体设备效率(OEE)报告的自动生成,并实时查看机器状态LMI带有内置RJ-45连接器,便于连接到以太网。

该设备有一个5.6英寸的彩色触摸屏,可以方便地访问编程功能。用户可以选择要收集的数据,包括零件计数和预设、废料计数、机器空闲时间和停机原因。收集的数据可以通过工号、工具号和/或零件号来识别。操作员编号也可以被捕获。借助LMI,制造商可以创建多达32个停机原因代码,并控制停机原因在终端上的显示顺序。

为了确保捕捉到重大停机事件,可以设置LMI,以防止机器在经过预设的闲置时间后重新启动,直到操作员输入适当的停机代码。霍尼韦尔为金属冲压和成型行业提供广泛的Wintriss自动化和安全产品组合。

Acton, MA, March 26, 2007 - Honeywell (NYSE :HON) Wintriss today introduced the LETS Machine Interface (LMI), an operator terminal that collects information from production machines. And enter Honeywell's Line Efficiency Tracking software (LETS).

Mark Hatch, Wintriss product line Director at Honeywell, said: "LMI allows us to provide powerful LETS system capabilities to customers whose production equipment lacks data collection capabilities. By installing one or more Lmis and connecting to the LETS, these customers can input production data into ERP or Manufacturing Execution system (MES) software, schedule automatic generation of production and overall equipment efficiency (OEE) reports, and view machine status in real time. The LMI comes with a built-in RJ-45 connector for easy connection to Ethernet.

The device has a 5.6-inch color touch screen for easy access to programming functions. Users can select the data to be collected, including part counts and presets, scrap counts, machine idle time, and downtime reasons. The collected data can be identified by job number, tool number, and/or part number. Operator numbers can also be captured. With LMI, manufacturers can create up to 32 stop cause codes and control the order in which the stop cause is displayed on the terminal.

To ensure that significant downtime events are captured, LMI can be set up to prevent the machine from restarting after a preset idle period until the operator enters the appropriate downtime code. Honeywell offers a broad portfolio of Wintriss automation and safety products for the metal stamping and forming industry.

QQ在线客服

QQ在线客服