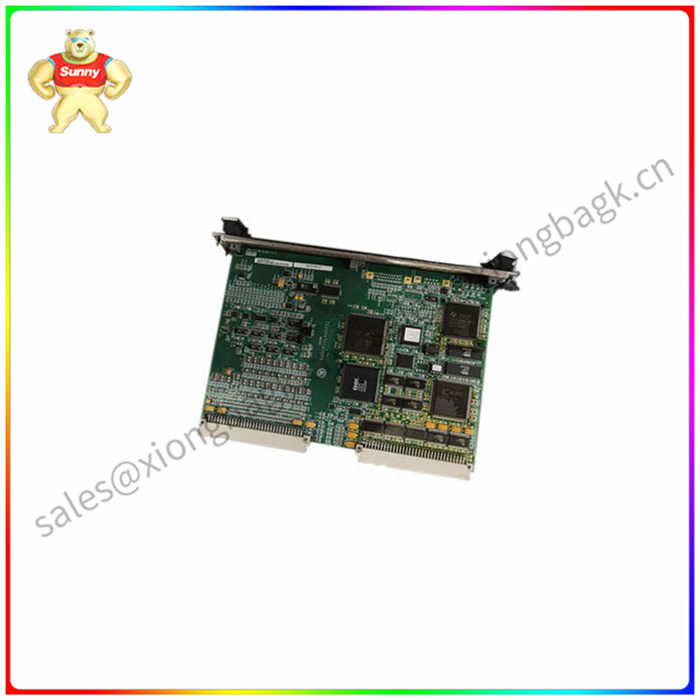

IS200TBA1H1CDC 可编程控制器

IS200TBA1H1CDC可编程控制器的主要特性:

强大的处理能力:具有强大的处理器,可处理复杂的控制算法和实时数据处理。

灵活的编程:利用灵活的编程语言来适应各种控制应用。

模块化设计:采用模块化设计,便于扩展和配置。

通信接口:提供用于连接其他系统组件和网络的通信接口。

坚固可靠:专为在恶劣的工业环境中稳健可靠地运行而设计。

IS200TBA1H1CDC可编程控制器的应用:

IS200TBA1H1CDC可编程控制器可作为多功能控制解决方案,适用于Mark VI涡轮机控制系统中的各种应用。包括:

涡轮机控制和监测:实施涡轮机控制和监测策略,以优化涡轮机的性能和效率。

顺序控制:执行复杂的顺序控制逻辑,实现涡轮子系统的自动化运行。

数据采集和处理:从传感器获取和处理数据,发射机和其他系统组件。

报警和事件管理:生成和管理警报和事件,以通知操作员潜在问题。

联锁和保护:实施联锁和保护计划,以保护涡轮机和人员。

总体而言,IS200TBA1H1CDC可编程控制器在Mark VI涡轮机控制系统的控制和自动化架构中起着至关重要的作用,为实施复杂的控制算法、数据处理和决策过程提供了一个灵活可靠的平台,以确保燃气轮机和蒸汽轮机的安全、高效和可靠运行。

IS200TBA1H1CDC 可编程控制器

Main features of IS200TBA1H1CDC Programmable controller:

Powerful processing power: A powerful processor that can handle complex control algorithms and real-time data processing.

Flexible programming: Use flexible programming languages to adapt to a variety of control applications.

Modular design: The modular design is easy to expand and configure.

Communication interface: Provides a communication interface for connecting other system components and networks.

Robust and reliable: Designed for robust and reliable operation in harsh industrial environments.

IS200TBA1H1CDC Programmable controller application:

The IS200TBA1H1CDC programmable controller can be used as a versatile control solution for a variety of applications in the Mark VI turbine control system. Includes:

Turbine control and monitoring: Implement turbine control and monitoring strategies to optimize turbine performance and efficiency.

Sequence control: Implement complex sequence control logic to automate the operation of turbine subsystems.

Data acquisition and processing: acquisition and processing of data from sensors, transmitters and other system components.

Alarm and Event Management: Generate and manage alerts and events to notify operators of potential issues.

Interlocking and protection: Implement an interlocking and protection plan to protect turbines and personnel.

Overall, the IS200TBA1H1CDC programmable controller plays a crucial role in the control and automation architecture of the Mark VI turbine control system, providing a flexible and reliable platform for implementing complex control algorithms, data processing and decision making processes to ensure the safe, efficient and reliable operation of gas and steam turbines.

QQ在线客服

QQ在线客服