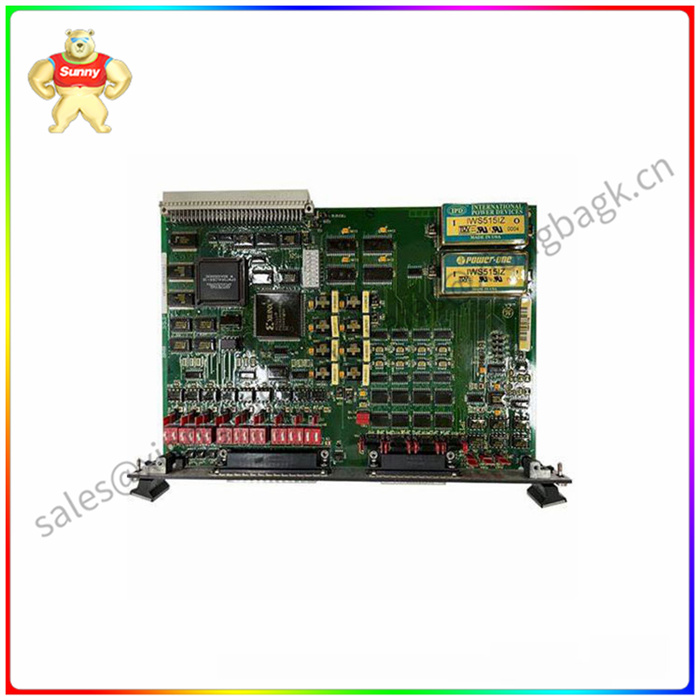

IS200TVBAH1AAA 振动端子板

产品概述

IS200T系列VBAH1AAA振动端子板是通用电气 (GE) 为其 Mark VIe 分布式控制系统 (DCS) 制造的专用组件。它用作连接和处理来自传感器的振动信号的接口,能够在各种工业应用中监测和分析机械的健康状况。

主要特点

振动信号处理:便于将来自传感器的振动信号转换为数字信号,以便由控制系统进行处理和解释。

传感器接口:提供用于连接振动传感器的专用接口,例如加速度计和接近传感器,监控机械运行状况并检测潜在故障。

信号调理:集成信号调理电路以放大,滤波器并线性化振动信号,确保准确可靠的数据采集。

高分辨率和高精度:在振动信号转换方面提供高分辨率和高精度,能够精 确分析机械的健康状况。

故障检测和诊断:提供故障检测和诊断功能,以识别和排除连接的振动传感器或信号调理电路的潜在问题。

应用

IS200TVBAH1AAA振动端子板可用于各种工业控制系统,特别是涉及机械健康监测和预测性维护的系统。 它在以下方面起着至关重要的作用:

状态监测:持续监测振动水平和模式,以检测机械磨损的早期迹象,疲劳和潜在的故障。

预测性维护:基于振动数据分析预测维护需求,支持主动维护计划,以zui大限度地减少停机时间并延长设备使用寿命。

根本原因分析:通过分析振动数据确定机械故障的根本原因,允许采取有针对性的纠正措施和预防措施。

性能优化:通过监测振动和确定需要改进的领域来优化机械性能,例如平衡或润滑调整。

总体而言,IS200TVBAH1AAA振动端子板是工业控制系统中的重要组件,能够有效地监控、分析和诊断机械的健康状况,有助于提高可靠性、减少停机时间和优化各种工业应用的性能。

IS200TVBAH1AAA 振动端子板

Product overview

The IS200T Series VBAH1AAA vibration terminal board is a special component manufactured by General Electric (GE) for its Mark VIe Distributed Control System (DCS). It is used as an interface to connect and process vibration signals from sensors, enabling monitoring and analysis of the health of machinery in a variety of industrial applications.

Main feature

Vibration signal processing: It is easy to convert vibration signals from sensors into digital signals for processing and interpretation by the control system.

Sensor interface: Provides a dedicated interface for connecting vibration sensors, such as accelerometers and proximity sensors, to monitor mechanical health and detect potential failures.

Signal conditioning: Integrated signal conditioning circuits amplify, filter and linearize vibration signals to ensure accurate and reliable data acquisition.

High resolution and high precision: provides high resolution and high precision in vibration signal conversion, enabling precise analysis of the health of the machinery.

Fault detection and diagnosis: Provides fault detection and diagnosis capabilities to identify and troubleshoot potential problems with connected vibration sensors or signal conditioning circuits.

Apply

The IS200TVBAH1AAA vibrating terminal board can be used in various industrial control systems, especially those involving mechanical health monitoring and predictive maintenance. It plays a vital role in:

Condition monitoring: Continuous monitoring of vibration levels and patterns to detect early signs of mechanical wear, fatigue and potential failures.

Predictive Maintenance: Predict maintenance needs based on vibration data analysis and support proactive maintenance plans to minimize downtime and extend equipment life.

Root cause analysis: Analysis of vibration data to determine the root cause of mechanical failure, allowing for targeted corrective action and preventive action.

Performance optimization: Optimize mechanical properties by monitoring vibration and identifying areas for improvement, such as balance or lubrication adjustments.

Overall, the IS200TVBAH1AAA vibration terminal board is an important component in industrial control systems that effectively monitors, analyzes, and diagnoses the health of machinery, helping to improve reliability, reduce downtime, and optimize performance in a variety of industrial applications.

QQ在线客服

QQ在线客服